MSP Submersible Slurry Pumps are designed to dewater the most abrasive sumps and ponds found in mining, Designed with high standard motors and cast high chrome wet-ends, these submersible slurry pumps have proven very reliable and an excellent alternative to the high maintenance vertical cantilever style pumps.

It mainly conveys media containing solid particles ( such as ore powder , ash , iron oxide scale , coal slime , mud sand and gravel , etc .) below 70°℃, suitable for mining , metallurgy , electric power , coal , river dredging , sand dredging and other industries . Capacity range: 25-5500 m3/h, Head range :9-135m, Power range: 4-560kw.

Technical Features:

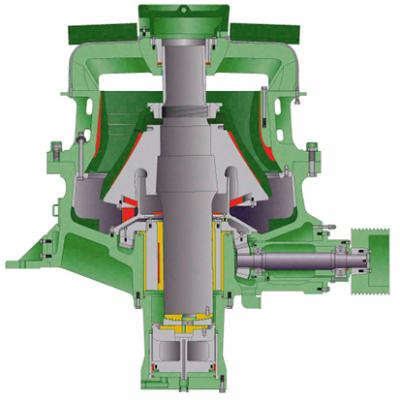

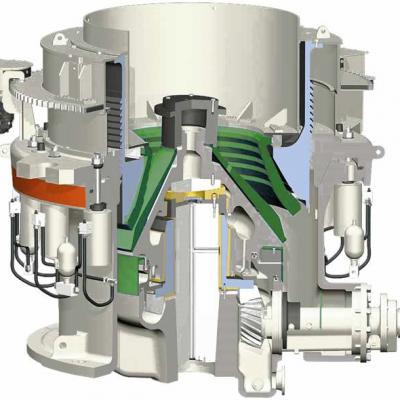

1. The pump shell and impeller are made of high chrome alloy material , the latest design of impeller , volute liner efficiency of more than 80%.

2. This pump adopts double mechanical seal design , one set of mechanical seal is installed in the oil chamber , another set contact with the transmission of medium liquid . Add cooling oil to the oil chamber to lubricate , cool and clean the mechanical seal, the service life is more than 30,000 hours .

3.The motor shell can be made of Q235 steel , which is better than ordinary cast iron to improve the protection level . The fastening screw is made of 316 material to ensure the operating life of the motor , which is twice longer than ordinary material .

4.The fixed rotor of the motor is with higher electromagnetic efficiency , electromagnetic copper wire Q2T/180 is high temperature resistant copper wire .

5. The motor structure is redesigned and optimized , supported by new bearing structure , and the motor shaft is treated with 4Cr13 conditioning . The motor ' s operating life is greatly extended , which is more than 2 times of the traditional motor .

6.Electric control can be customized 380V-600V voltage range ,50-60Hz frequency . Monitoring and protection using PLC screen display can realize the pump group operation bearing temperature , sealing leakage , motor overheating and other problems

7.The connection of cable and motor adopts secondary protection design to protect the motor .

8.The equipment can be fixed or moveable installation .

Advantanges :

1. The pump runs smoothly and freely , without jamming and stagnation ;

2. After the assembly of the pump , the sealing device on one side of the pump was subjected to air pressure test , the test pressure was 3bar, and the test lasted for 5min without leakage ;

3. The design service life of the mechanical seal is not less than 15000 hours , the service life of the bearing is not less than 50000 hours ; The service life of the equipment is no less than 2 years .

4. All sealing parts of the pump are subjected to pressure test without leakage , the test pressure is 3bar, lasting 5min;

5. The pump nameplate is marked with obvious rotation direction ;

6. Dynamic balance test of pump impeller and rotor , balance accuracy grade is G6.3;

7. When the pump is used at full head , the power curve is stable ;

8. The pump runs continuously in the pumping medium and is allowed to start 15 times per hour without affecting the service life .

Matec Solutions Co.,Ltd.

Matec Solutions Co.,Ltd.