Applications:

Mill Discharge, Cyclone Feeding, Concentration Plant Processing, Tailing Pumping, Chemical Slurry, Quarry

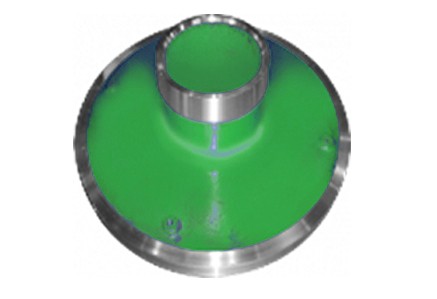

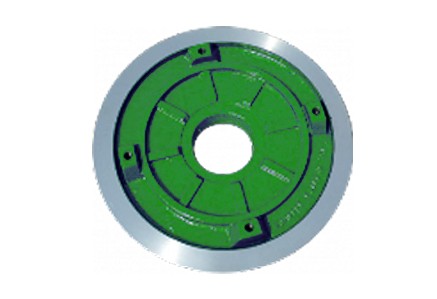

Wraman Pump Parts Equivalent:

AH:1.5/1B, 2/1.5B, 3/2C, 4/3C, 4/3D, 6/4D, 6/4E, 8/6E, 8/6R,10/8F, 10/8ST, 12/10ST, 14/12ST, 16/14TU, 20/18TU;

HH: 1.5/1C, 3/2D, 4/3E, 6/4F, 8/6S;

L: 50B, 75C, 100D, 150E, 300F, 350S, 400ST, 450ST, 550TU, 650TU;

M: 10/8E, 10/8F, 12/10E, 12/10F;

G: 6/4D, 8/6E, 10/8S, 12/10ST, 14/12G, 18/16T;

SP: 40P, 65Q, 100R, 150S, 200S, 250T, 300T;

MCR: 350, 450, 550, 650 .

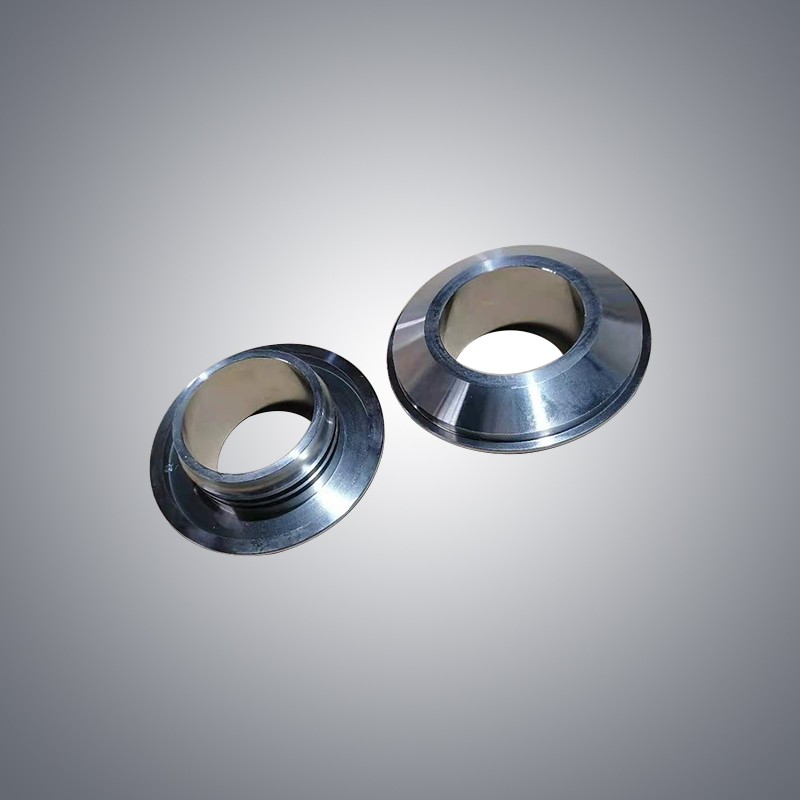

Materials Specification:

Alloy A05 is a wear resistant white cast iron that offers excellent performance under erosive conditions, hardness is over 600HB. It works well for mild acidic duties (PH5-14) where erosion resistance is required;

Alloy A07 is a martensitic white iron having a reasonable combination of wear resistance and toughness. Hardness 700-800, PH 6-12, recommended for very abrasive mill discharge application;

Alloy A61 is a hypereutectic white iron, suitable for high wear duties, where corrosion is not severe. pH range 6 to 14. The alloy may provide up to three times the life of A05, hardness 650HB;

Alloy A49 is a corrosion resistant white iron suitable for low pH corrosion duties, where erosive wear is also a problem, particularly suitable for FGD applications.

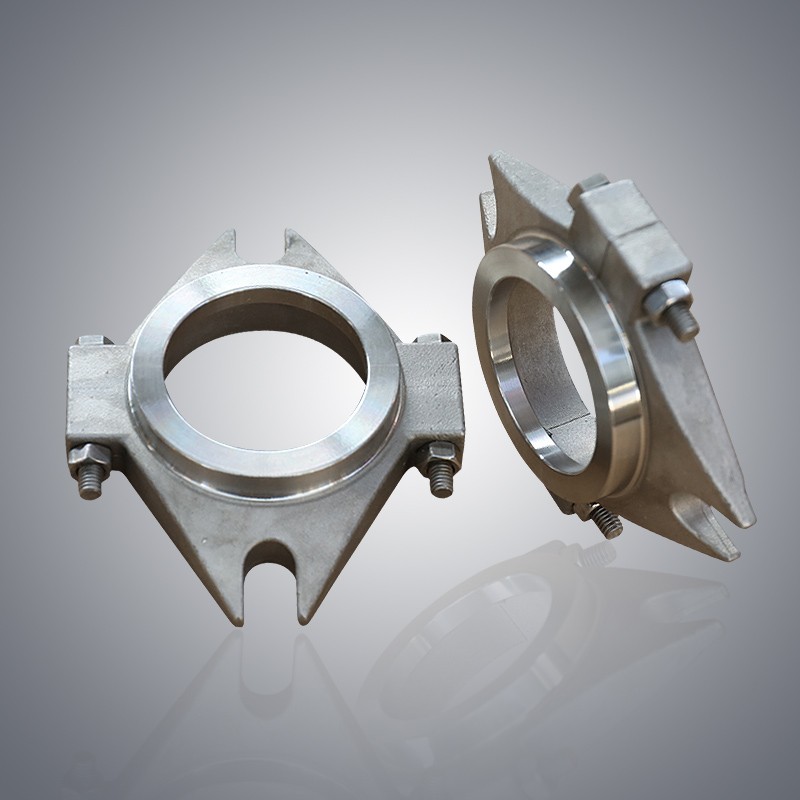

Features:

Optimized alloy material with higher anti-abrasiveness and toughness, to ensure longer service life, easpecially for heavy duty applications like mill discharge, cyclone feeding and tailings;

Higher performance and efficiency, durable structure, more uptime, less labor, lower cost of ownership.

Matec Solutions Co.,Ltd.

Matec Solutions Co.,Ltd.