Welcome to our blog post on maximizing impact crusher performance with Metso NP Series parts. As technology continues to advance and the demand for efficient and high-performing crushers increases, it is crucial for companies in the mining and aggregates industries to stay ahead of the game. The use of impact crushers has become a popular choice due to their ability to reduce large rocks into smaller sizes, making them highly beneficial in various applications. However, like any machinery, regular maintenance and proper usage are essential for optimal performance. In this blog post, we will delve into how using Metso NP Series parts can significantly enhance the efficiency, reliability, and longevity of your impact crusher while also reducing downtime and increasing overall profitability. So let's dive in!

Understanding the Role of Blow Bars in Impact Crushers

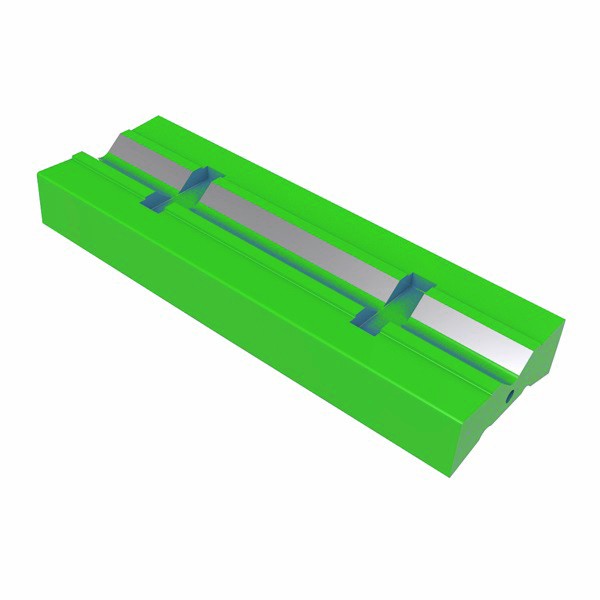

Impact crushers are essential pieces of machinery in many industries, and understanding their various components is crucial to ensure their efficient and effective operation. One such component is the blow bar, which plays a central role in crushing the material and ensuring that the final product meets the required specifications. Blow bars are usually made of manganese steel, chromium, or titanium, and they come in different shapes and sizes to suit different applications. They work by absorbing the impact of the material as it enters the crusher, and then redirecting the energy back into the crushing process. By understanding the role of blow bars, operators can prolong the lifespan of their equipment, reduce maintenance costs and downtime, and produce high-quality products that meet customer needs.

The Importance of Wear Parts for Crusher Efficiency and Longevity

Crushers are essential equipment for any mining or construction operation. They break down large materials into smaller, more manageable pieces for processing, transporting, and storing. However, the wear and tear on these machines can be significant, leading to costly repairs and downtime. That's where wear parts come in. These specialized components are designed to withstand the wear and tear of daily use, providing long-lasting performance and maximum efficiency. By investing in high-quality wear parts, you can help extend the life of your crusher and ensure that it operates at peak performance for years to come. So whether you're running a small quarry or a large mining operation, choosing the right wear parts is critical to your success.

Enhancing Durability with Breaker Plate Liners and Side Wear Plates

When it comes to heavy machinery like crushers or shredders, durability is everything. That's where breaker plate liners and side wear plates come in. By adding these components, you can extend the lifespan of your equipment and decrease the likelihood of breakdowns or the need for repairs. These liners and plates are designed to withstand the most punishing work environments and can prevent damage to your machines caused by abrasive materials or constant wear. By enhancing your equipment with these components, you're making a smart investment in the longevity of your machinery and ensuring that your operations run smoothly for years to come.

In conclusion, we now have a thorough understanding of the crucial role that blow bars play in impact crushers. These wear parts are essential for maximizing crusher efficiency and ensuring its longevity. By properly selecting and maintaining high-quality blow bars, crusher operators can significantly enhance their equipment's durability and performance. Additionally, equipping crushers with breaker plate liners and side wear plates can further improve their overall functionality. These components work together to protect the crusher from excessive wear and tear, ultimately resulting in reduced downtime and increased productivity. Investing in top-grade blow bars and other wear parts is not only beneficial for the equipment but also for the operators' bottom line. It allows them to save on costly repairs and replacements while maintaining a high level of production. Ultimately, understanding the importance of these wear parts will lead to smoother operations, increased profitability, and overall customer satisfaction. So don't overlook the significance of blow bars – they may seem like small parts, but their impact on crushers is immense! Make sure to stay proactive in maintaining them to ensure your crushers operate at peak efficiency and keep your business thriving for years to come.

Matec Solutions Co.,Ltd.

Matec Solutions Co.,Ltd.