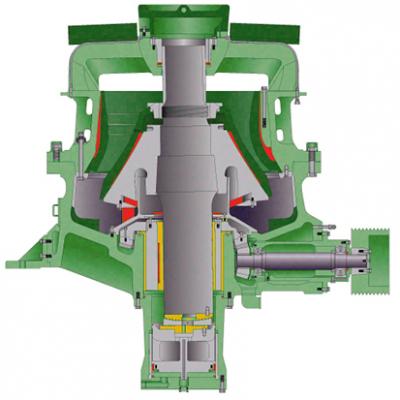

A wide range of vortex finder sizes are available for each cyclone model. The vortex finder size has the greatest effect on cyclone performance for any given cyclone size. the smaller the vortex finder, the finer the classification and the lesser the capacity of the cyclone.

The spigot diameter is generally the most convenient variable to adjust or change, it has greatest effect on the underflow density of the cyclone. In general, a decrease in spigot diameter will increase the underflow density and improve the efficiency of the classification.

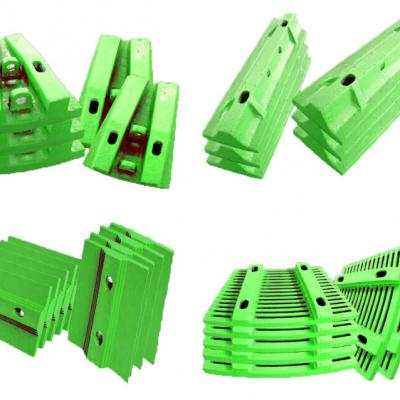

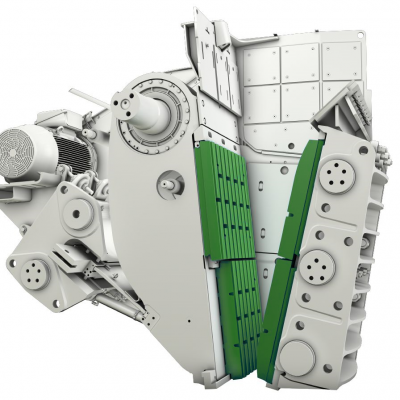

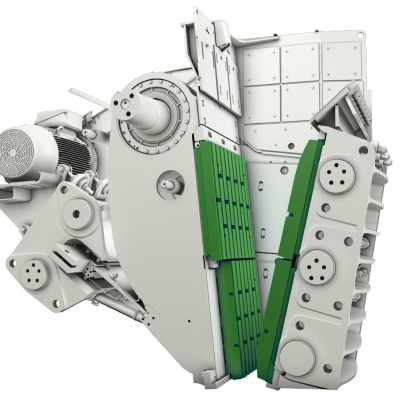

Main Components: Cover Plate Liner/Feed chamber/ Vortex Finder/Cone Liners/Spigot-Apex

Applications:As an universal separating and classifying equipment, widely used for mineral processing, desliming, thickening and also dewatering operations.

Features & Specifications:

Dimension accuracy and Compatibility is guaranteed;

Superior abrasion resistance for a longer wear life.

High wear resistant Polyurethane

Polyurethane elastomer is of high strength, corrosion resistance, light weight, wide hardness range. Polyurethane with casting solidification has good wear resistance, it is especially suitable for medium and fine particle with long service life.

Matec Solutions Co.,Ltd.

Matec Solutions Co.,Ltd.